Cylinder wheels are a type of grinding wheel that have a cylindrical shape and a flat grinding surface on one or both ends. These wheels are commonly used for surface grinding and cylindrical grinding operations, where the workpiece is held in place and rotated against the grinding wheel.

Cylinder wheels are made from a variety of abrasive materials, including aluminum oxide, silicon carbide, and diamond. The abrasive particles are bonded together with a variety of materials, such as vitrified bonds, resin bonds, or metal bonds.

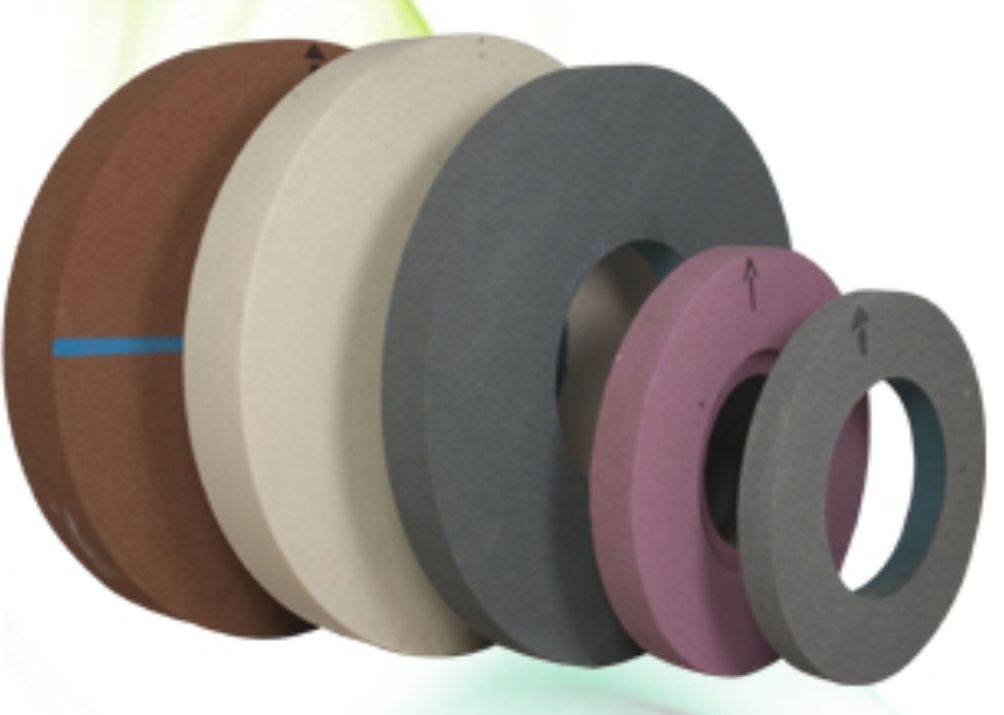

Cylinder wheels are available in a range of sizes, with diameters ranging from a few millimeters to several hundred millimeters. The size and shape of the wheel depend on the specific grinding application and the size and shape of the workpiece being ground.

When using cylinder wheels, it is important to choose the appropriate grit size and bond type for the specific grinding application. It is also important to follow safety guidelines, such as wearing appropriate personal protective equipment, inspecting the wheel for cracks and damage before use, and following proper grinding techniques.

No Comments